Optimized Efficiency

FEV Test Benches in Aachen to receive new Automation

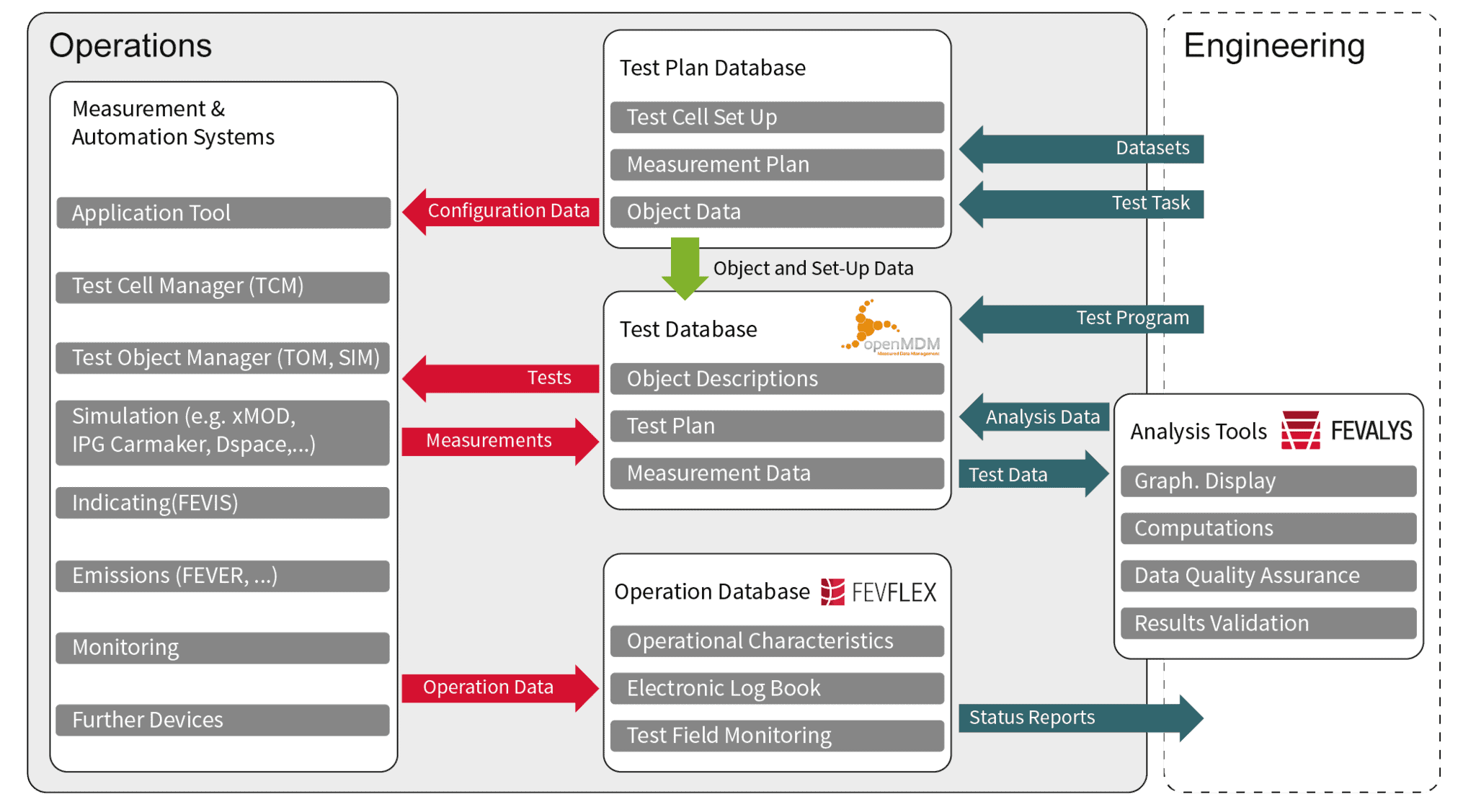

The FEV test benches in Aachen have undergone extensive modernization. The purpose of these technical updates is to renew the electrical/electronic and measurement equipment, media conditioning equipment, and enhance the automation of a total of 10 engine test benches. Through state-of-the-art automation and efficient crosslinking with other systems, the modernization measures make a significant contribution toward increasing the efficiency of the test benches in Aachen. FEV’s customers consistently benefit from this efficiency improvement. The latest version of the proven FEV automation system and the high-performance, model-based control of the FEV Test Object Manager (TOM) are used for test bench automation. Dynamic mode switching enables the selection of the appropriate mode within a running test cycle. This allows an ideal representation of transient torque / speed (M/n) controlled tests and prevents motoring during dynamic cycles. Thanks to direct communication between the TOM and the powertrain control module, highly dynamic engine braking – as it is often realized on commercial vehicles by intervention in the valve timing controls – can be perfectly reproduced on the test bench. In order to ensure fast interaction between test bench automation and Test Object Manager, as well as between other, external simulation systems, high-performance EtherCAT interfaces are available. Accordingly, the automation system offers extensive, scalable simulation options that start with a simple intrinsic Road Load Simulation (RLS) and a TOM-internal, model-based driver/vehicle simulation (SIM) up through connections with comprehensive simulation environments such as DSpace, IPG Carmaker, or xMOD. A wide variety of additional advantages with regard to efficiency, system configuration, and data processing are made possible by the intuitive graphic definition of testing sequences within the Test Schedule Manager (TSM), the device driver concept, as well as variability in the selected parameter names via optional representations and data storage that can be freely chosen within the standardized FEV naming universe (or within any client-specific naming universe). The test bench automation systems within FEV’s Aachen test field are fully integrated into an information management system. This system links information from the test planning phase, data acquisition, data management, and data post-processing. openMDM is used as a test database and is the central tool for managing measurement data. This includes, for example, management of data that is time-synchronized within FEV, coming from the application environment, gas and particulate emissions measurement technology, combustion analysis systems, and many other measures. In doing so, the openMDM database acts as bi-directional communication platform between testing operations and development. This enables efficient collaboration between the FEV specialist units.

High-Performance Automation

Integrated Information Management