FEV Brings the Fuel Cell to the Street

Integration of a Fuel Cell Range Extender in a Subcompact Category Vehicle

280 kilometers range without refill, a high-speed of 120 km/h, and zero emissions: In the BREEZE! project, FEV developed a fuel cell range extender and integrated it into an existing battery-electric vehicle (BEV) in the subcompact category. To show the capabilities in terms of very small packaging, the engineers decided for a Fiat 500 based BEV which represents a particular challenge with respect to existing space. The FIAT 500 was selected from FEV’s E-vehicle fleet.

Range extender concepts (REX) are designs that feature serial hybrid powertrains in which the drive power is provided primarily through an external, rechargeable battery, as opposed to plug-in hybrids, where the primary functions of the battery are to provide boosting, brake energy regeneration, load point shifting, or local, emission-free driving in urban traffic.

Dimensioning of the Range Extender

In the design layout, the REX-performance was compared with the drive power of the BEV and FEV experts chose a scenario-based design instead of a cycle-based approach, so the battery can provide the full vehicle power even when the battery is at a low State-of-Charge (SoC). As a result, the vehicle has a top speed of 120 km/h regardless of the SoC and also has a small performance reserve, so that uphill slopes and highway travel do not have to be entirely compensated by using the battery.

Due to installation space restrictions, the range of the battery is 80 km while the additional range of approximately 200 km, provided by the REX fuel cells, is limited by the size of the hydrogen tank. However, a tank refill of hydrogen can be completed within a few short minutes, and travel can be continued at the same maximum speed.

The volume of the cell stacks is approximately 15.5 l, leading to a volumetric gross power density of 2.2 kW/l. With a volume of 67 l, the entire REX module achieves a volumetric gross power density of 0.45 kW/l and a gravimetric gross power density of 0.25 kW/l, including operating materials. The fuel cell range extender thus lies in the same range as combustion engine range extenders.

Package-Optimized System Design

The space available in the Fiat 500 is very limited. For this reason, FEV fitted the entire REX module into the spare wheel area while the tank is located under the rear seat. This made extensive measures and precise planning necessary to integrate the module, various components, auxiliary equipment, and sensors which are necessary to supply the fuel cell with air, hydrogen, and coolant.

Modular Vehicle Integration:

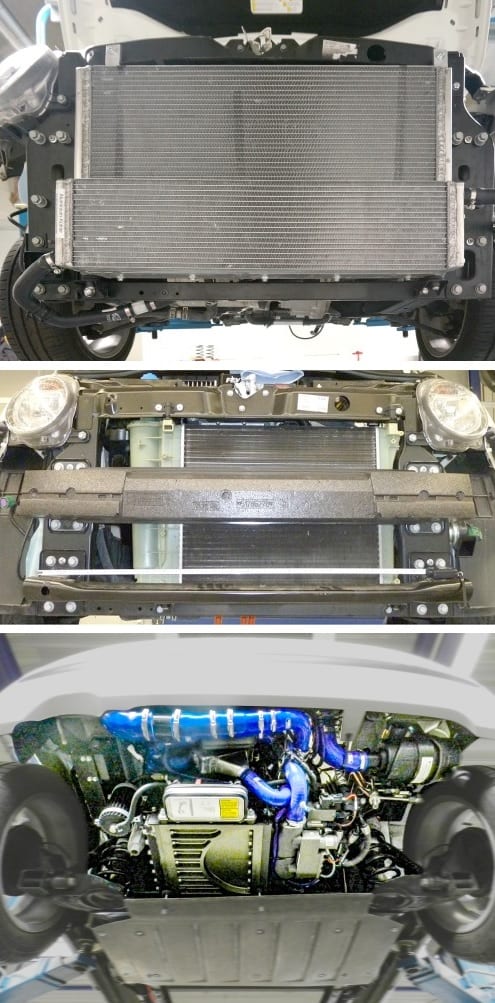

For the vehicle integration concept, all required components, were grouped into functional modules and assigned to available vehicle installation spaces. The cooling module, consisting of an expansion tank, an ion exchanger, a low-temperature cooler for the traction machine, power electronics, and a high-temperature cooler for the REX fuel cells, is built into the front-end of the vehicle. The other components which directly influence the operation of the fuel cell are consolidated in the REX module. Most of the components were directly integrated into the end plate of the fuel cell.

The medium pressure (MP) system turned out to be a suitable interface to the hydrogen and distribution module, since the pressure reducer and the safety valve were not available as components that could be integrated. With the exception of refuelling function, the HP system functions are grouped in the tanking valve. Due to the dimensions of the available pressurized hydrogen tanks, the maximum tank volume is achieved as a weight-saving, single-tank system, located under the rear seat with a 34 l type III tank.

The mechanical requirements for the REX module arising from vehicle integration were considered in the concept development of the structural components. The clamping elements of the stack are designed in such a way that they offer massive attachment points, sufficient for connection to the engine mounts in the vehicle that are independent of temperature or operation-related changes in cell stack length. These structural components, some of which are integrated into the module housing, can absorb forces and bending torques on the order of 5g during driving operation which arise from both horizontal and vertical acceleration, without compromising the integrity of the cell stack or safe operation of the module. The compatibility of the stack with vibration stimuli was confirmed for all three axes on a vibration test bench with a random vibration test, in accordance with ISO12405-1.

Powertrain Design

On the air side, the system is supplied with air through an electrically powered radial compressor, the Rotrex C8-8, electrified by FEV and the VKA. The aspirated air is purified of any particles or harmful gases, such as volatile organic compounds (VOC, e.g. butane or toluene), or sulfur dioxide, via an air filter. Prior to entry in the cell stack, the air temperature is also conditioned in a heat exchanger. Before the oxygen-depleted exhaust gas is released into the environment, it passes through a muffler.

On the hydrogen side, the system is supplied by a type III high-pressure tank that can be refilled via an SAE J2600-compliant tank nozzle at any hydrogen tanking station. This tank nozzle immobilizes the vehicle during the filling process to prevent the vehicle from rolling during refueling.

SAE J2600-compliant tank nozzles for the various pressure levels (250, 350, 700 bar) are downwards compatible with the filling nozzles, meaning that a vehicle with a 700-bar tank can also be filled at a 350-bar tanking station, but not the other way around. The hydrogen passes from the high-pressure (HP) system to the medium-pressure (MP) system via a pressure reducer and from there to the cell stack via a dosing valve. The pressure on the anode side is based on the cathode pressure with regard to a constant differential pressure. The accumulation of inert gases such as nitrogen and water vapor, is dissipated by a purge valve. Liquid water in the anode gas downstream of the cell stack is separated in a water separator and recirculated via a combination of fan and a jet pump. The liquid water then passes through a valve and, eventually, into the cathode exhaust.

Focus on Safety

Various sensors on both the air side and hydrogen side including those for pressure, temperature, mass flow, and hydrogen concentration measurement assure comprehensive system safety monitoring. In the event of a fire that inadmissibly heats up the tank, or in the case of an inadmissible pressure rise in the medium pressure system, hydrogen is vented to the environment via separate venting lines, to prevent component bursting and uncontrolled release of hydrogen gas (TPRD – thermally activated pressure relief device). The hydrogen system meets the requirements of EC79/2009 and all of the components used in the system are certified.

In vehicle fuel cell systems, all supplied and extracted media come in contact with the high-voltage poles and the vehicle ground. Accordingly, these media channels are potential failure sources for the insulation. Dry air and dry hydrogen may be bad electric conductors, but by the time they reach the cell stack exit, they have been humidified with product water from the fuel cell and the gas flow may carry some particles or fibers, which may consist of graphite, from the gas diffusion layer increasing the conductivity of the gases. Accordingly, the design of media channels, especially for serial applications, should also include design features that ensure maintenance intervals, even under unfavorable conditions.

In addition, the tank nipple immobilizes the vehicle during the refuelling process to prevent the vehicle from driving away during refuelling.

Challenging Thermal Management

Compared to the series production radiator in the combustion engine-powered Fiat 500, a significantly larger cooler with increased fan power is required for the fuel cell system. This is necessary since fuel cells, unlike combustion engines, release their heat almost exclusively via the coolant and at a lower temperature level. Depending on the load point, this temperature is between 60 and 80°C. The selected cooler enables operation of REX at the design point with no additional airflow and an ambient temperature of 20°C. With an ambient temperature of 40°C, this performance can be provided starting at a speed of 80 km/h. Thus, even steeper mountain stages are possible at an ambient temperature of 40°C. This cooler, as well as the intercooler are fluxless pure aluminum radiators to keep the electrical conductivity of the coolant flow low.